Solid Brass Kitchen Tap refers to kitchen faucets manufactured with a high proportion of brass as the main structural material. These products are designed with material stability, manufacturing consistency, and long-term reliability as core principles. Brass itself possesses excellent mechanical strength and corrosion resistance, making it suitable for use in kitchen environments where it is constantly exposed to water and temperature fluctuations. Therefore, it is widely used in the mid-to-high-end kitchen hardware sector. solid brass kitchen taps are typically manufactured using integral casting or precision machining processes for the main body, followed by surface treatment to enhance appearance consistency and oxidation resistance. In a procurement context, this keyword primarily refers to material properties and manufacturing standards, rather than a specific design or functional configuration. For engineering clients, brands, and channel buyers, Solid Brass kitchen tap represents a controllable quality level and a stable supply base, facilitating subsequent structural customization, appearance differentiation, or functional module combinations. These products usually conform to internationally recognized interface specifications, making them easy to integrate into different market systems and meeting the needs of long-term bulk deliveries.

| Item | Parameter |

| Model Number | 19S-206 |

| Color | Chrome, Matte Black |

| Certification | / |

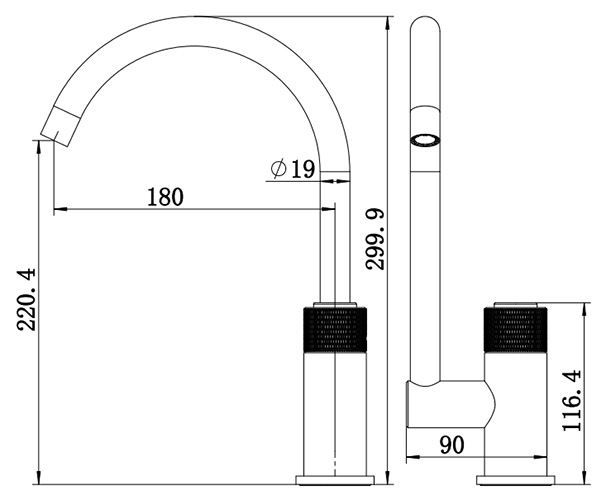

| Products | Kitchen Mixer with keypad switch, Ø35mm, Brass body, Brass handle, Ceramic cartridge, Two G1/2-450mm flexible hoses. |

Trade Terms: FOB Jiangmen base on Amount of one time order reach to $10,000 USD.

● If the order Amount is less than $10,000 USD, the price will be just as EXW price.

● If the goods need to send to other port which farther than Jiangmen, our factory will charge the difference on freight.

Packing: With package in cloth bag and white inner box each unit, kraft carton box.Also, we can customized packaging base on you need.

Order Lead Time: Within 35-45 days after receive 30% deposits.

Payment Terms:

● T/T - 30% pay before production , 70% will pay before delivery.

● T/T - one off pay for the sample order.

1. Solid Brass Construction

The Solid Brass Kitchen Tap uses high-density brass as its main material. The overall structure is completed through a one-piece molding process, avoiding structural risks associated with multi-section splicing. The brass body exhibits stable pressure resistance under standard operating conditions, adapting to common water supply pressure ranges. The Ø35mm valve core seat structure provides reliable support for internal components, ensuring that the structure remains unchanged under long-term operation. The internal water channels are precisely machined to reduce water flow resistance and minimize noise. This structure is suitable for continuous high-frequency use scenarios and meets engineering-grade durability requirements. The material consistency of the Solid Brass Kitchen Tap facilitates batch quality control.

2. Digital Keypad Switching Design

This Solid Brass Kitchen Tap integrates a keypad switching module for precise control of water flow. The keypad components are separated from the main structure to reduce wear and tear during long-term use. The control module operates within rated electrical and mechanical parameters, adapting to common kitchen usage patterns. The structural design focuses on reliable trigger feedback, reducing the probability of accidental operation. The surface of the keypad area is treated to maintain consistent tactile feel over time. This design is suitable for project-based procurement requiring high operational precision.

3. Ceramic Valve Core System

The product uses a ceramic valve core structure with a diameter of Ø35mm, conforming to industry standard specifications. The ceramic discs are precision-ground to ensure smooth and stable opening and closing. The valve core assembly maintains a stable sealing state under rated water pressure conditions. Long-term opening and closing tests demonstrate reduced maintenance frequency. The high precision fit between the valve core and the brass body reduces the risk of internal leakage. Therefore, the Solid Brass Kitchen Tap offers predictable service life performance.

4. Standard Interfaces and Hose Configuration

This Solid Brass Kitchen Tap is equipped with two G1/2 interface stainless steel braided hoses, each 450mm long, meeting conventional installation requirements. The interface size is compatible with mainstream water supply systems, facilitating quick installation in different regions. The hose structure maintains its shape within the rated pressure range. The precision machining of the interface threads helps improve sealing reliability. The overall connection system reduces the difficulty of on-site adjustments. This configuration is suitable for batch engineering delivery and standardized installation processes.

5. Surface Treatment and Customization Capabilities

The product surface is available in two common finishes: Chrome and Matte Black, to match different kitchen styles. The surface treatment process is controlled to ensure wear resistance and stable adhesion. Color consistency is well-controlled in mass production. The brass body and surface layer are securely bonded, reducing the risk of peeling during long-term use. OEM/ODM projects are supported for adjustments to appearance, structure, and branding. This solid brass kitchen tap is suitable for brand customers looking to expand their product lines.

1. High-End Residential Kitchens

In high-end residential kitchen spaces, Solid Brass Kitchen Taps emphasize material stability and long-term performance. These environments typically have specific requirements for the structural reliability of hardware products. The brass body helps withstand the physical stress of frequent use. The key-operated switching design enhances operational clarity. Standard interface configurations facilitate integration with the overall kitchen system. This application scenario focuses on consistent long-term performance.

2. Apartment Renovation Projects

Apartment renovation projects emphasize installation efficiency and controllable after-sales service, and Solid Brass Kitchen Taps offer structural advantages in such projects. Uniform valve cores and interfaces facilitate batch construction. The brass material maintains stable quality performance during concentrated delivery periods. The key-operated structure reduces the risk of complaints due to operational errors. The product configuration facilitates unified maintenance. This scenario is more suitable for standardized procurement models.

3. Commercial Showroom Kitchens

Showroom kitchens typically serve display and trial purposes, requiring consistency in appearance and feel. The surface treatment of Solid Brass Kitchen Taps helps maintain a stable display state. The key-operated switching method enhances product recognition. Structural stability supports high-frequency demonstration operations. Standard specifications facilitate quick replacement or layout adjustments. This application focuses on the overall presentation effect of the product.

4. Long-Term Rental Apartment Kitchens

Long-term rental apartment kitchens prioritize durability and maintenance cycles, making Solid Brass Kitchen Taps suitable for this type of operating environment. The brass body reduces structural wear and tear under long-term use. The ceramic valve core reduces the need for frequent repairs. Standard hoses and interfaces facilitate unified replacement. The key-operated design helps standardize usage. This application emphasizes life cycle cost control.

5. Engineering Delivery Residential Projects

In engineering delivery residential projects, Solid Brass Kitchen Taps focus more on batch consistency and delivery stability. The product structure helps meet centralized procurement standards. Uniform parameter configurations facilitate the engineering acceptance process. Surface treatment solutions adapt to different project positioning. OEM/ODM support allows brands to differentiate their appearance. This scenario focuses on supply chain collaboration capabilities.