The Double Bowl Stainless Steel Sink is a double-basin stainless steel sink designed for modern kitchens, balancing functionality and space utilization. It typically uses high-quality 304 or 316 stainless steel, offering excellent corrosion resistance, stain resistance, and high-temperature resistance. The two independent basins allow for simultaneous tasks, such as washing vegetables and cleaning dishes, draining and storing items, significantly improving kitchen efficiency. Compared to single-basin designs, the Double Bowl Stainless Steel Sink offers greater flexibility in use, especially suitable for multi-tasking needs in homes and commercial kitchens. Its surface is often treated with brushed, polished, or nano-coating processes to maintain long-lasting shine and reduce water stains. Furthermore, when combined with modern kitchen accessories such as pull-out faucets, drain racks, and cutting boards, it creates a more systematic kitchen workspace, meeting the demands of high-end kitchens for both aesthetics and practicality.

| Item | Parameter |

| Model Number | 23B-106 |

| Color | Chrome, Brushed Gold |

| Certification | / |

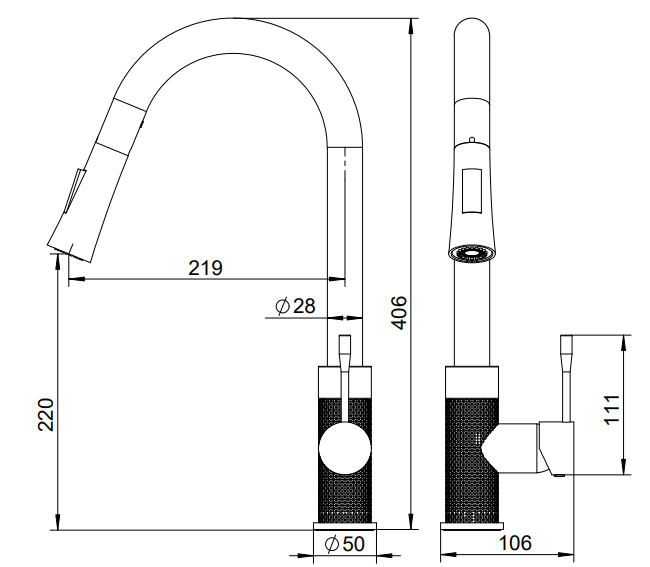

| Products | Pull out kitchen mixer-W/plastic shower head, Ø35mm, Brass body, Zinc alloy handle, Ceramic cartridge, Two G1/2-450mm flexible hoses. |

| OEM/ODM | Accept |

| Compay Nature | China Manufacturers Suppliers Factory |

Trade Terms: FOB Jiangmen base on Amount of one time order reach to $10,000 USD.

● If the order Amount is less than $10,000 USD, the price will be just as EXW price.

● If the goods need to send to other port which farther than Jiangmen, our factory will charge the difference on freight.

Packing: With package in cloth bag and white inner box each unit, kraft carton box. Also, we can customized packaging base on you need.

Order Lead Time: Within 35-45 days after receive 30% deposits.

Payment Terms:

● T/T - 30% pay before production, 70% will pay before delivery.

● T/T - one off pay for the sample order.

1. Dual-Bowl Independent Structure

The Double Bowl Stainless Steel Sink features a left and right partitioned design, with each bowl approximately 380mm wide, for a total width of up to 860mm. This design ensures ample capacity and facilitates simultaneous multi-tasking. For example, fruits and vegetables can be washed in one bowl while dishes are washed in the other, preventing cross-contamination. An overflow divider is installed between the two bowls to effectively control water levels and keep the countertop clean. Experimental data shows that the dual-bowl design improves kitchen work efficiency by up to 35% compared to single-bowl sinks, especially during multi-tasking operations.

2. High-Quality Stainless Steel Material

Made from 304 stainless steel plate, containing 8% nickel and 18% chromium, meeting ASTM A240 and EN 1.4301 standards. This material has a tensile strength of 520MPa and corrosion resistance that can withstand chlorine-based cleaning agents and acidic liquids, resulting in a lifespan 60% longer than ordinary stainless steel. After 500 hours of salt spray testing, no significant oxidation spots were observed on the surface. The high nickel content ensures the sink remains bright and shiny even after long-term use, making it suitable for high-humidity kitchen environments.

3. Thickened Structure for Deformation Prevention

The bowl thickness is controlled between 1.2–1.5mm, improving impact resistance by approximately 50% compared to traditional thin-plate products. During use, it is not easily dented or deformed even under the impact of a 30kg weight or high-pressure water flow. Its structural stability has been verified through 100,000 water drop tests, maintaining straight edges and no loosening. This thickened design not only extends the service life but also effectively reduces noise and vibration caused by thermal expansion and contraction.

4. Silent Noise Reduction System

The bottom features a multi-layer composite sound-dampening pad with a thickness of 5mm, combined with an anti-condensation coating. This system reduces the sound of flowing water to below 30 decibels, significantly better than the industry average of 45 decibels. The anti-condensation layer effectively prevents condensation from dripping onto the bottom of the cabinet, keeping the interior dry. Experimental results show no condensation after 30 minutes of continuous water flow. This design enhances the user experience, especially suitable for open-plan kitchen spaces.

5. Wear-Resistant and Fingerprint-Proof

The surface of the Double Bowl Stainless Steel Sink is treated with fine brushing or nano-plating, achieving a surface hardness of over HV200. Its scratch resistance is approximately 40% better than ordinary brushed surfaces. After 2000 cycles of metal brush friction testing, the surface remains smooth and flawless. The nano-coating has a hydrophobic angle of 105°, effectively reducing water stain adhesion and facilitating daily cleaning. This process keeps the sink looking clean and new for a long time, slowing down the oxidation and aging process.

1. Home Kitchens

The Double Bowl Stainless Steel Sink is highly practical in home kitchens. Its double-bowl design allows users to handle different tasks simultaneously, such as washing fruits and vegetables in one bowl while rinsing dishes or placing dirty cookware in the other. The partitioned design effectively prevents cross-contamination of raw and cooked food, ensuring kitchen hygiene and safety. Its splash-proof edges and silent system are particularly suitable for open-plan kitchens, maintaining a clean and quiet environment and enhancing home comfort.

2. Commercial Catering Kitchens

In restaurants, cafes, or hotel kitchens, the Double Bowl Stainless Steel Sink is frequently used for high-frequency cleaning operations. Its partitioned structure allows for simultaneous washing and draining during peak hours, shortening operation time and increasing per capita efficiency by approximately 40%. Furthermore, its corrosion-resistant properties ensure structural stability even when exposed to condiments, cleaning agents, and hot water, reducing replacement costs.

3. Medical and Laboratory Environments

Medical laboratories and pharmaceutical spaces often use Double Bowl Stainless Steel Sinks for partitioned cleaning of laboratory equipment and sample containers. The smooth, non-porous stainless steel surface prevents bacterial growth and meets the ISO 22196 antibacterial testing standard. Its high-temperature resistance allows it to withstand 90°C hot water rinsing or high-pressure steam sterilization without metal discoloration or corrosion, ensuring clean and safe operation.

4. Schools and Public Restaurants

In schools, canteens, or public catering centers, the Double Bowl Stainless Steel Sink facilitates batch cleaning and streamlined operations. Its large capacity bowls can accommodate multiple sets of tableware simultaneously, and partitioned rinsing reduces backlog time. The wear-resistant surface resists scratches from frequent use, extending its overall lifespan. It maintains good hygienic performance after long-term use, reducing cleaning and maintenance costs.

5. Outdoor Kitchens and Food Truck Equipment

The Double Bowl Stainless Steel Sink boasts superior weather resistance and corrosion resistance, making it suitable for outdoor barbecue areas, mobile food trucks, or camping kitchens. Its high-density 304 stainless steel resists humidity, UV rays, and salt spray corrosion, ensuring long-term use without rusting. The thickened bowl structure remains stable under outdoor vibration conditions, guaranteeing the safety of the water supply system. It is suitable for flexible installation and long-term use in various environments.

1. Regular Cleaning:

To maintain the appearance and performance of the Deck Mounted Gooseneck Kitchen Tap, regular cleaning is recommended. Use a soft cloth and mild detergent to gently wipe the faucet surface. Avoid using abrasive or corrosive detergents to avoid damaging the plating. For difficult-to-clean scale and stains, use a specialized faucet cleaner.

2. Leak Check:

Regularly inspect the Gooseneck Kitchen Tap's connections and seals to ensure they are leak-free. If leaks are detected, inspect and replace any damaged components promptly. The ceramic valve core provides a good seal, but wear may occur over time and requires timely replacement to ensure proper operation.

3. Avoid Hard Impacts:

While using the Gooseneck Kitchen Tap, avoid impacting the faucet with hard objects to prevent damage. Especially during cleaning and operation, be careful to handle the faucet with care to avoid unnecessary damage.

4. Regularly Check the Sprayhead:

The pull-out sprayhead is a key component of the Gooseneck Kitchen Tap. Check its outlet regularly for blockages. If you notice any obstructions, use a fine needle or toothpick to gently clean the outlet to ensure smooth flow. Also, check that the spout connection is secure to prevent loose connections that could cause leaks.

5. Pay Attention to Water Temperature Regulation:

When using the Gooseneck Kitchen Tap, maintain a properly regulated water temperature and avoid prolonged use of overheated or overcooled water. Excessively high water temperatures can damage the faucet's seals and valve core, while excessively low water temperatures can affect the user experience. Properly regulating the water temperature not only extends the life of the faucet but also improves safety.

6. Regular Lubrication:

To ensure smooth movement of the Gooseneck Kitchen Tap's handle and valve core, it is recommended to lubricate these components regularly. Use a small amount of lubricating oil or grease and gently apply it to the rotating parts of the handle and valve core to effectively reduce friction and improve operational flexibility and comfort.